Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

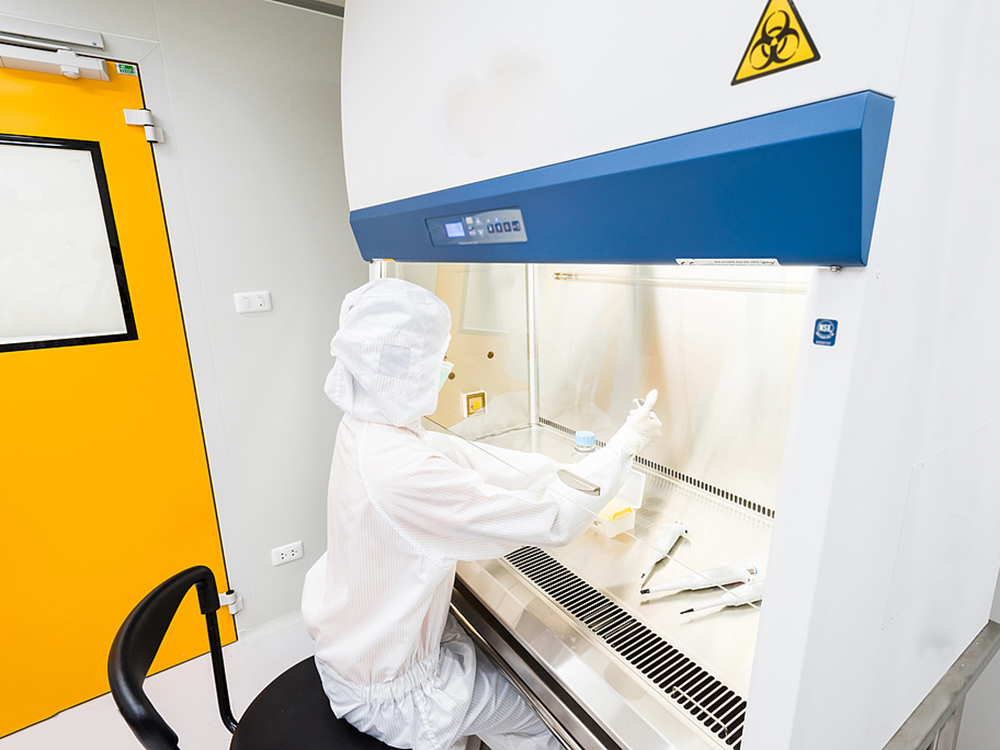

The Essential Guide to Cleanroom Cleaning Products

In controlled environments where microscopic contaminants can cause major problems, specialized cleaning tools make all the difference. Let's examine the critical features of professional cleanroom cleaning products and how to select the right solutions for your facility.

Understanding Cleanroom Cleaning Requirements

Cleanrooms demand cleaning products that outperform ordinary supplies. Unlike regular cleaning tools that can introduce contaminants, true cleanroom products must:

-

Eliminate particle generation during use

-

Withstand sterilization processes when required

-

Meet strict ISO classification standards

-

Maintain integrity during cleaning procedures

The consequences of using improper cleaning tools can be severe - from compromised pharmaceutical batches to defective microchips. This makes product selection a critical decision.

Cleanroom Wipes: The First Line of Defense

High-performance cleanroom wipes serve as the workhorses of contamination control. Esun's microfiber wipes demonstrate the qualities needed for sensitive environments:

Constructed from 100% continuous microfiber filament, these wipes achieve true lint-free performance. Their tightly woven structure prevents fiber shedding while delivering exceptional absorbency for solvents and cleaning solutions.

These wipes prove particularly valuable in:

-

Semiconductor fabrication cleanrooms

-

Sterile pharmaceutical manufacturing

-

Medical device assembly areas

-

Aerospace component production

Available in both disposable and reusable formats, they adapt to various cleanroom protocols and cleaning frequencies.

The Cleanroom Mop Selection Guide

Different cleaning challenges require specialized mop designs. Here's a breakdown of five professional-grade options:

1. Dust Control Microfiber Mop

This single-use workhorse combines an 80% polyester/20% polyamide cleaning surface with a durable nonwoven backing. Its lightweight design allows technicians to cover large areas efficiently while maintaining contamination control.

2. Scrubbing Mop for Tough Contaminants

When facing stubborn residues, the microfiber scrubbing mop delivers. Its unique design incorporates abrasive polyester stripes to loosen debris while surrounding microfiber areas capture and contain particles.

3. Twist Mop for Deep Cleaning

The 100% polyester twisted loop construction creates an ideal balance of particle capture and surface cleaning. The knitted backing provides durability for extended use in ISO-classified environments.

4. Stripe Mop for Comprehensive Cleaning

This hybrid design merges particle-capturing microloops with polypropylene scrubbing stripes. Folded edges enable thorough corner cleaning, while the high-absorbency material maximizes efficiency.

5. Ultrasonic Lamination Mop for Critical Environments

Representing the pinnacle of cleanroom mop technology, this sterile option utilizes ultrasonic bonding to eliminate particle shedding. With 285% absorbency and coverage up to 21m² per mop, it sets new standards for cleanroom cleaning performance.

Implementing an Effective Cleaning Program

Selecting quality products represents just one component of contamination control. Proper implementation requires:

-

Matching products to your cleanroom classification

-

Establishing standardized cleaning protocols

-

Training staff on proper techniques

-

Implementing regular quality checks

Where to Source Reliable Cleanroom Products

Esun's comprehensive line of cleanroom cleaning supplies meets the diverse needs of controlled environments. Their products undergo rigorous testing to ensure:

-

Consistent particle control performance

-

Reliable material durability

-

Compliance with international standards

For facilities ranging from electronics manufacturing to pharmaceutical production, investing in proper cleanroom cleaning tools isn't optional - it's fundamental to operational success.

By understanding these product differences and applications, maintenance teams can make informed decisions that protect product quality and process integrity. The right cleaning tools, when used properly, become powerful assets in contamination prevention strategies.

Would you like specific recommendations for your cleanroom classification or industry application? Our experts can help tailor a cleaning solution to your exact requirements.